Tds blowdown control valves VPC 26S

When a steam boiler is in operation there is continuous evaporation of boiler water which causes an undesirable increase in TDS (Total Dissolved Solids) concentration. A typical problem that results from this is water foaming, which leads to reduced boiler performance and wet steam. Furthermore, dissolved and suspended solids will carry over into the steam lines, contaminating valves, tubes, heat exchangers and steam traps, leading to corrosion, scaling and erosion. For these reasons, a certain amount of boiler water must be discharged continuously or periodically to ensure TDS concentration is kept within the recommended parameters.

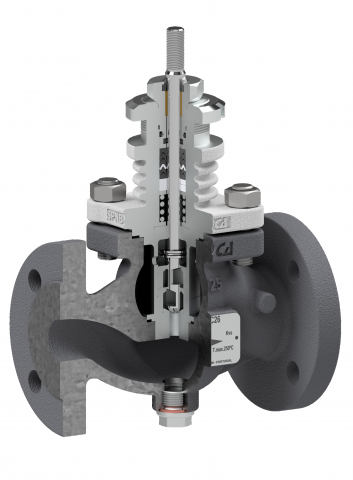

The ADCATrol VPC26 is a control valve specially designed for this purpose and features a multi-stage trim to progressively reduce the energy of the fluid. This makes it ideal for discharge of boiler blowdown at high differential pressures where flashing is a concern.

The valve is suitable for both continuous and on/off TDS control via a PA series reverse action pneumatic actuator or AV series fail-safe spring return actuator.

- Minimized vibrations due to continuous stem guiding.

- Seat and plug sealing surfaces are protected fom erosion at low stroke positions.

- Compact and modular design.

- Multi stage trim for controlled velocity and pressure drop.

- Hardened stainless steel trim with stellite faced plug and seat.

- Tool-free quick exchangeable clamped-in seats, allowing fast and easy inline maintenance procedures.

- Sample valve bottom connection.

- NV400B sample valve.

- Blowdown controllers.

- TDS probes.

TDS blowdown control in steam boilers and other applications with high pressure drops and low flow rates where cavitation and flashing phenomenon are likely to occur.

VPC26S – carbon steel.

VPC26i – stainless steel.

1/2" to 11/2"; DN 15 to DN 40.

Flanged EN 1092-1 PN 40.

Flanged ASME B16.5 Class 300.

PA10 linear pneumatic actuator.

AVF234S linear electric actuator.