- Intermittent discharge.

- Integral air vent.

- Standard insulation cover.

- Operates on superheated steam.

- The seat and disc can be easily replaced in field without removing the trap from the line.

- Unaffected by water hammer and vibrations.

- Built-in easy-to-clean strainer.

Thermodynamic

Thermodynamic Steam trap DT 40/2

The thermodynamic DT40/2 disc steam traps are compact and lightweight-easy to install traps, excellent for high pressure systems, including steam tracing applications.

The insulation cover ensures a consistent operation and makes it particularly suitable for those applications where the weather conditions, such as rain and wind, may affect the normal operation.

These traps have only one moving part and offer a wide operating range, without adjustment.

Saturated and superheated steam.

DT40/2 – stainless steel.

3/8” to 1”; DN 10 to DN 25.

Female threaded ISO 7 Rp or NPT.

Flanged EN 1092-1 PN 40.

Flanged ASME B16.5 Class 150 or 300.

Socket weld (SW) ASME B16.11.

Butt weld (BW) ASME B16.25 on request.

Horizontal or vertical installation.

See IMI – Installation and maintenance instructions.

Thermodynamic Steam trap DT 46

The thermodynamic DT46 disc steam traps are compact and lightweight-easy to install traps, excellent for high pressure systems, including steam tracing applications.

The insulation cover ensures a consistent operation and makes it particularly suitable for those applications where the weather conditions, such as rain and wind, may affect the normal operation.

These traps have only one moving part and offer a wide operating range, without adjustment.

- Intermittent discharge.

- Integral bimetallic air vent to avoid air blockage.

- Complete with insulation cover to reduce heat and efficiency losses.

- Operates with superheated steam.

- The seat and disc can be easily replaced in field without removing the trap from the line.

- Hardened seat and disk with duly lapped surface for longer service life.

- Unaffected by water hammer and vibrations.

- Built-in easy-to-clean strainer.

- Blow-out proof seat gaskets suitable for high pressure conditions.

- Blowdown valve.

Saturated and superheated steam.

DT46 – carbon steel.

1/2" to 1"; DN 15 to DN 25.

Female threaded ISO 7 Rp or NPT.

Flanged EN 1092-1 PN 40, PN 63 or PN 100.

Flanged ASME B16.5 Class 150, 300 or 600.

Socket weld (SW) ASME B16.11.

Butt weld (BW) ASME B16.25 on request.

Horizontal or vertical installation.

See IMI – Installation and maintenance instructions

Thermodynamic steam traps DT42/2

The thermodynamic DT42/2 disc steam traps are compact and lightweight-easy to install traps, excellent for high pressure systems, including steam tracing applications.

These traps have only one moving part and offer a wide operating range, without adjustment.

- Intermittent discharge.

- Operates on superheated steam.

- The seat and disc can be easily replaced in field without removing the trap from the line.

- Unaffected by water hammer and vibrations.

- Built-in easy-to-clean strainer.

- Insulation cover.

- Blowdown valve

- USE: Saturated and superheated steam.

Saturated and superheated steam.

DT 42/2 – carbon steel

DT42/2 – carbon steel.

Female threaded ISO 7 Rp or NPT.

Flanged EN 1092-1 PN 40 or PN 63.

Flanged ASME B16.5 Class 150 or 300.

Socket weld (SW) ASME B16.11.

Butt weld (BW) ASME B16.25 on request

Horizontal or vertical installation.

See IMI – Installation and maintenance instructions

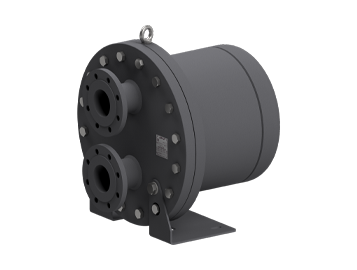

Float

Float and thermostatic steam traps FLT312 and FLT314

The FLT312 and FLT314 are a series of high capacity float and thermostatic steam traps with integral air vent, designed for modulating discharge of condensate to ensure maximum system heat transfer.

Specially designed for applications where continuous drainage is essential and high loads are involved.

- High capacity.

- Modulating discharge of condensate at steam temperature.

- Unaffected by sudden or wide load and pressure variations.

- No backing-up with condensate.

- Excellent air discharge through its integrated thermostatic air vent.

- Equalizing (vent) and drain connections.

- HVV – Hand vent valve.

- BDV – Blowdown valve.

- AFZ – Anti-freeze device.

- VB21M – Vacuum breaker.

Saturated and superheated steam.

FLT312S and FLT314S – carbon steel.

FLT312S – 2”; DN 50.

FLT314S – 21/2”; DN 65.

Flanged EN 1092-1 PN 16.

Flanged ASME B16.5 Class 150.

Horizontal installation.

See IMI – Installation and maintenance instructions.

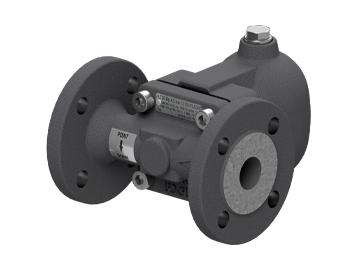

Float and thermostatic steam traps FLT50 and FLT65

The FLT50 and FLT65 are a series of high capacity float and thermostatic steam traps with integral air vent, designed for modulating discharge of condensate to ensure maximum system heat transfer.

Specially designed for applications where continuous drainage is essential and high loads are involved.

- High capacity.

- Modulating discharge of condensate at steam temperature.

- Unaffected by sudden or wide load and pressure variations.

- No backing-up with condensate.

- Excellent air discharge through its integrated thermostatic air vent.

- Equalizing (vent) and drain connections.

Saturated and superheated steam.

FLT50S and FLT65S – carbon steel.

FLT50S – 2” to 21/2”; DN 50 to DN 65.

FLT65S – 21/2” to 4”; DN 65 to DN 100.

Flanged EN 1092-1 PN 16.

Flanged ASME B16.5 Class 150

Angled horizontal installation.

See IMI – Installation and maintenance instructions.

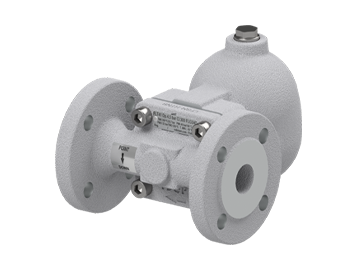

Float and thermostatic steam traps FLT80

The FLT80S float and thermostatic steam traps series (with integral air vent) are designed for all types of low and high pressure steam heating and process equipment.

Typical applications include unit heaters, heat exchangers, driers, jacketed vessels and all the applications where continuous drainage is essential.

- Modulating discharge.

- Discharges condensate at steam temperature.

- Unaffected by sudden or wide load and pressure changes.

- Excellent air discharge (by thermostatic air vent).

Equalizing plug or vent connection.

Saturated and superheated steam.

FLT80S – carbon steel.

3” and 4”; DN 80 and DN 100.

Flanged EN 1092-1 PN 16.

Flanged ASME B16.5 Class 150.

Horizontal standard installation with vertical inlet and horizontal outlet.

See IMI – Installation and maintenance instructions.

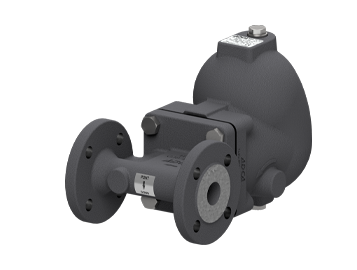

Float and thermostatic steam traps FLT314TW

he FLT314TW is a series of high capacity float and thermostatic steam traps with integral air vent, designed for modulating discharge of condensate to ensure maximum system heat transfer.

Specially designed for applications where continuous drainage is essential and high loads are involved.

- High capacity.

- Modulating discharge of condensate at steam temperature.

- Unaffected by sudden or wide load and pressure variations.

- No backing-up with condensate.

- Excellent air discharge through its integrated thermostatic air vent.

- Equalizing (vent) and drain connections.

- HVV – Hand vent valve.

- BDV – Blowdown valve.

- AFZ – Anti-freeze device.

- VB21M – Vacuum breaker.

Saturated and superheated steam.

FLT314STW – carbon steel.

3” – DN 80.

Flanged EN 1092-1 PN 16.

Flanged ASME B16.5 Class 150.

Horizontal installation.

See IMI – Installation and maintenance instructions.

Float and thermostatic steam traps FLT16

The FLT16 is a series of float and thermostatic steam traps with integral air vent designed for modulating discharge of condensate, ensuring maximum system heat transfer.

Typical applications include unit heaters, heat exchangers, dryers, jacketed vessels and other applications where continuous discharge is essential.

- Modulating discharge of condensate at steam temperature.

- Unaffected by sudden or wide load and pressure variations.

- No backing-up with condensate.

- Excellent air discharge through its integrated air vent.

- Equalizing (vent) and drain connections.

- SLR – Steam lock release.

- HVV – Hand vent valve.

- BDV – Blowdown valve.

- AFZ – Anti-freeze device.

- VB21M – Vacuum breaker

Saturated and superheated steam.

FLT16-4,5 , 10 and 14 – SG iron.

1/2" and 3/4"; DN 15 and DN 20.

Female threaded ISO 7 Rp or NPT.

Flanged EN 1092-2 PN 16

Horizontal installation from right to left (R-L).

See IMI – Installation and maintenance

instructions.

On request: horizontal installation from left to

right (L-R) or vertical from top to bottom (V).

MAX. ΔP

FLT16-4,5 – 4,5 bar

FLT16-10 – 10 bar

FLT16-14 – 14 bar

Float and thermostatic steam traps FLT20 (SG iron ; 1/2" to 1" – DN 15 to 25)

The FLT20 is a series of float and thermostatic steam traps with integral air vent designed for modulating discharge of condensate, ensuring maximum system heat transfer.

Typical applications include unit heaters, heat exchangers, dryers, jacketed vessels and other applications where continuous discharge is essential.

- Modulating discharge of condensate at steam temperature.

- Unaffected by sudden or wide load and pressure variations.

- No backing-up with condensate.

- Excellent air discharge through its integrated air vent.

- Flow direction can be easily changed by repositioning the body in relation to the mechanism and cover.

- Equalizing (vent) and drain connections.

- SLR – Steam lock release.

- HVV – Hand vent valve.

- BDV – Blowdown valve.

- AFZ – Anti-freeze device.

- VB21M – Vacuum breaker.

Saturated and superheated steam.

FLT20-4,5 , 10 and 14 – SG iron.

1/2" to 1"; DN 15 to DN 25.

Female threaded ISO 7 Rp or NPT.

Flanged EN 1092-1/-2 PN 16.

Flanged ASME B16.42 Class 150.

Inline horizontal or vertical installation.

Angled horizontal or vertical installation.

See IMI – Installation and maintenance instructions.

MAX. ΔP

FLT20-4,5 – 4,5 bar

FLT20-10 – 10 bar

FLT20-14 – 14 bar

Float and thermostatic steam traps FLT21 (SG iron ; 1/2" to 1" – DN 15 to 25)

The FLT21 is a series of float and thermostatic steam traps with integral air vent designed for modulating discharge of condensate, ensuring maximum system heat transfer.

Typical applications include unit heaters, heat exchangers, dryers, jacketed vessels and other applications where continuous discharge is essential.

- Modulating discharge of condensate at steam temperature.

- Unaffected by sudden or wide load and pressure variations.

- No backing-up with condensate.

- Excellent air discharge through its integrated air vent.

- Flow direction can be easily changed by repositioning the body in relation to the mechanism and cover.

- Equalizing (vent) and drain connections.

- SLR – Steam lock release.

- HVV – Hand vent valve.

- BDV – Blowdown valve.

- AFZ – Anti-freeze device.

- FLL – Float lifting lever.

- VB21M – Vacuum breaker.

Saturated and superheated steam.

FLT21-4,5 , 10 and 14 – SG iron.

1/2" to 1"; DN 15 to DN 25.

Female threaded ISO 7 Rp or NPT.

Flanged EN 1092-1/-2 PN 16.

Flanged ASME B16.42 Class 150.

Inline horizontal or vertical installation.

Angled horizontal or vertical installation.

See IMI – Installation and maintenance instructions.

Float and thermostatic steam traps FLT30 (Carbon steel 1/2” – 1”; DN 15 – 25)

The FLT30 is a series of float and thermostatic steam traps with integral air vent designed for modulating discharge of condensate, ensuring maximum system heat transfer.

Typical applications include unit heaters, heat exchangers, dryers, jacketed vessels and other applications where continuous discharge is essential.

- Modulating discharge of condensate at steam temperature.

- Unaffected by sudden or wide load and pressure variations.

- No backing-up with condensate.

- Excellent air discharge through its integrated air vent.

- Flow direction can be easily changed by repositioning the body in relation to the mechanism and cover.

- Equalizing (vent) and drain connections.

- SLR – Steam lock release.

- HVV – Hand vent valve.

- BDV – Blowdown valve.

- AFZ – Anti-freeze device.

- VB21M – Vacuum breaker.

Saturated and superheated steam.

FLT30-4,5 , 10, 14 and 21 – carbon steel.

1/2” to 1”; DN 15 to DN 25.

Female threaded ISO 7 Rp or NPT.

Flanged EN 1092-1 PN 40.

Flanged ASME B16.5 Class 150 or 300.

Socket weld (SW) ASME 16.11.

Inline horizontal or vertical installation.

Angled horizontal or vertical installation.

See IMI – Installation and maintenance instructions.

MAX. ΔP

FLT30-4,5 – 4,5 bar

Float and thermostatic steam traps FLT31 (Carbon steel 1/2” – 1”; DN 15 – 25)

The FLT31 is a series of float and thermostatic steam traps with integral air vent designed for modulating discharge of condensate, ensuring maximum system heat transfer.

Typical applications include unit heaters, heat exchangers, dryers, jacketed vessels and other applications where continuous discharge is essential.

- Modulating discharge of condensate at steam temperature.

- Unaffected by sudden or wide load and pressure variations.

- No backing-up with condensate.

- Excellent air discharge through its integrated air vent.

- Flow direction can be easily changed by repositioning the body in relation to the mechanism and cover.

- Equalizing (vent) and drain connections.

- SLR – Steam lock release.

- HVV – Hand vent valve.

- BDV – Blowdown valve.

- AFZ – Anti-freeze device.

- FLL – Float lifting lever.

- VB21M – Vacuum breaker.

Saturated and superheated steam.

FLT31-4,5 , 14, 10, 21 and 32 – carbon steel.

1/2” to 1”; DN 15 to DN 25.

Female threaded ISO 7 Rp or NPT.

Flanged EN 1092-1 PN 40.

Flanged ASME B16.5 Class 150 or 300.

Socket weld (SW) ASME 16.11.

Inline horizontal or vertical installation.

Angled horizontal or vertical installation.

See IMI – Installation and maintenance instructions

MAX. ΔP

FLT31-4,5 – 4,5 bar

FLT31-10 – 10 bar

FLT31-14 – 14 bar

FLT31-21 – 21 bar

FLT31-32 – 32 bar

Float and thermostatic steam traps FLT41 (Stainless steel 1/2” – 1”; DN 15 – 25)

The FLT41 is a series of float and thermostatic steam traps with integral air vent designed for modulating discharge of condensate, ensuring maximum system heat transfer.

Typical applications include unit heaters, heat exchangers, dryers, jacketed vessels and other applications where continuous discharge is essential.

- Modulating discharge of condensate at steam temperature.

- Unaffected by sudden or wide load and pressure variations.

- No backing-up with condensate.

- Excellent air discharge through its integrated air vent.

- Flow direction can be easily changed by repositioning the body in relation to the mechanism and cover.

- Equalizing (vent) and drain connections.

- SLR – Steam lock release.

- HVV – Hand vent valve.

- BDV – Blowdown valve.

- AFZ – Anti-freeze device.

- FLL – Float lifting lever.

- VB21M – Vacuum breaker.

Saturated and superheated steam.

FLT41-4,5 , 10, 14 , 21 and 32 – stainless steel.

1/2” to 1”; DN 15 to DN 25.

Female threaded ISO 7 Rp or NPT.

Flanged EN 1092-1 PN 40.

Flanged ASME B16.5 Class 150 or 300.

Socket weld (SW) ASME 16.11.

Inline horizontal or vertical installation.

Angled horizontal or vertical installation.

See IMI – Installation and maintenance instructions.

MAX. ΔP

FLT41-4,5 – 4,5 bar

FLT41-10 – 10 bar

FLT41-14 – 14 bar

FLT41-21 – 21 bar

FLT41-32 – 32 bar

Float and thermostatic steam traps FLT25 (SG iron ; 1" – DN 25)

The FLT25 is a series of float and thermostatic steam traps with integral air vent designed for modulating discharge of condensate, ensuring maximum system heat transfer.

Typical applications include unit heaters, heat exchangers, dryers, jacketed vessels and other applications where continuous discharge is essential.

- Modulating discharge of condensate at steam temperature.

- Unaffected by sudden or wide load and pressure variations.

- No backing-up with condensate.

- Excellent air discharge through its integrated air vent.

- Flow direction can be easily changed by repositioning the body in relation to the mechanism and cover.

- Equalizing (vent) and drain connections.

- SLR – Steam lock release.

- HVV – Hand vent valve.

- BDV – Blowdown valve.

- AFZ – Anti-freeze device.

- FLL – Float lifting lever.

- VB21M – Vacuum breaker.

Saturated and superheated steam.

FLT25-4,5 , 10 and 14 – SG iron.

1"; DN 25.

Female threaded ISO 7 Rp or NPT.

Flanged EN 1092-1/-2 PN 16.

Flanged ASME B16.42 Class 150

Inline horizontal or vertical installation.

Angled horizontal or vertical installation.

See IMI – Installation and maintenance instructions

MAX. ΔP

FLT25-4,5 – 4,5 bar

FLT25-10 – 10 bar

FLT25-14 – 14 bar

Float and thermostatic steam traps FLT35 (Carbon steel 1”; DN 25)

The FLT35 is a series of float and thermostatic steam traps with integral air vent designed for modulating discharge of condensate, ensuring maximum system heat transfer.

Typical applications include unit heaters, heat exchangers, dryers, jacketed vessels and other applications where continuous discharge is essential.

- Modulating discharge of condensate at steam temperature.

- Unaffected by sudden or wide load and pressure variations.

- No backing-up with condensate.

- Excellent air discharge through its integrated air vent.

- Flow direction can be easily changed by repositioning the body in relation to the mechanism and cover.

- Equalizing (vent) and drain connections.

- SLR – Steam lock release.

- HVV – Hand vent valve.

- BDV – Blowdown valve.

- AFZ – Anti-freeze device.

- FLL – Float lifting lever.

- VB21M – Vacuum breaker.

Saturated and superheated steam.

FLT35-4,5 , 10, 14, 21 and 32 – carbon steel.

1”; .DN 25

Female threaded ISO 7 Rp or NPT.

Flanged EN 1092-1 PN 40.

Flanged ASME B16.5 Class 150 or 300.

Socket weld (SW) ASME 16.11

Inline horizontal or vertical installation.

Angled horizontal or vertical installation.

See IMI – Installation and maintenance instructions.

MAX. ΔP

FLT35-4,5 – 4,5 bar

FLT35-10 – 10 bar

FLT35-14 – 14 bar

FLT35-21 – 21 bar

FLT35-32 – 32 bar

Float and thermostatic steam traps FLT45 (Stainless steel 1”; DN 25)

The FLT45 is a series of float and thermostatic steam traps with integral air vent designed for modulating discharge of condensate, ensuring maximum system heat transfer.

Typical applications include unit heaters, heat exchangers, dryers, jacketed vessels and other applications where continuous discharge is essential.

- Modulating discharge of condensate at steam temperature.

- Unaffected by sudden or wide load and pressure variations.

- No backing-up with condensate.

- Excellent air discharge through its integrated air vent.

- Flow direction can be easily changed by repositioning the body in relation to the mechanism and cover.

- Equalizing (vent) and drain connections.

- SLR – Steam lock release.

- HVV – Hand vent valve.

- BDV – Blowdown valve.

- AFZ – Anti-freeze device.

- FLL – Float lifting lever.

- VB21M – Vacuum breaker.

Saturated and superheated steam.

FLT45-4,5 , 10, 14, 21 and 32 – stainless steel

1”; DN 25.

Female threaded ISO 7 Rp or NPT.

Flanged EN 1092-1 PN 40.

Flanged ASME B16.5 Class 150 or 300

Socket weld (SW) ASME 16.11

Inline horizontal or vertical installation.

Angled horizontal or vertical installation.

See IMI – Installation and maintenance instructions.

MAX. ΔP

FLT45-4,5 – 4,5 bar

FLT45-10 – 10 bar

FLT45-14 – 14 bar

FLT45-21 – 21 bar

FLT45-32 – 32 bar

Float and thermostatic steam traps FLT22

The FLT22 is a series of high capacity float and thermostatic steam traps with integral air vent, designed for modulating discharge of condensate to ensure maximum system heat transfer.

Specially designed for applications where continuous drainage is essential and high loads are involved.

- High capacity.

- Modulating condensate discharge at steam temperature.

- Unaffected by sudden load and pressure changes.

- Excellent air discharge.

Saturated and superheated steam superheated

FLT22S-4,5, 10, 14 and 21 - carbon steel.

FLT22SS-4,5, 10, 14 and 21 - stainless steel.

Female thread ISO 7 Rp or NPT.

Flanges EN 1092-1 PN 25.

Flanges ASME B16.5 Class 150 or 300.

Standard horizontal installation from right to left (R-L). See IMI -

Installation and maintenance instructions.

On request: Left to right (L-R) or vertical installation from top to bottom (V).

top to bottom (V).

MAX. ΔP

FLT22S-4.5 - 4.5 bar

FLT22S-10 - 10 bar

FLT22S-14 - 14 bar

FLT22S-21 - 21 bar

Note: the same same figures are valid for FLT22SS.

Float and thermostatic steam traps FLT27 (SG iron ; 11/2" and 2" – DN 40 and 50)

The FLT27 is a range of float and thermostatic steam traps with integral air vent designed for modulating discharge of condensate, ensuring maximum system heat transfer.

Typical applications include unit heaters, heat exchangers, dryers, jacketed vessels and other applications where continuous discharge is essential and high flow capacities are involved.

- Modulating discharge of condensate at steam temperature.

- Unaffected by sudden or wide load and pressure variations.

- No backing-up with condensate.

- Excellent air discharge through its integrated air vent.

- Flow direction can be easily changed by repositioning the body in relation to the mechanism and cover.

- Equalizing (vent) and drain connections.

- SLR – Steam lock release.

- HVV – Hand vent valve.

- BDV – Blowdown valve.

- AFZ – Anti-freeze device.

- FLL – Float lifting lever.

- VB21M – Vacuum breaker.

Saturated and superheated steam.

FLT27-4,5 , 10 and 14 – SG iron

11/2" and 2"; DN 40 and DN 50

Female threaded ISO 7 Rp or NPT.

Flanged EN 1092-2 PN 16.

Flanged ASME B16.42 Class 150

Horizontal or vertical installation.

MAX. ΔP

FLT27-4,5 – 4,5 bar

FLT27-10 – 10 bar

FLT27-14 – 14 bar

Float and thermostatic steam traps FLT37 (Carbon steel 11/2” – 2”; DN 40 – 50)

The FLT37 is a range of float and thermostatic steam traps with integral air vent designed for modulating discharge of condensate, ensuring maximum system heat transfer.

Typical applications include unit heaters, heat exchangers, dryers, jacketed vessels and all applications where continuous discharge is essential and high flow capacities are involved.

- Modulating discharge of condensate at steam temperature.

- Unaffected by sudden or wide load and pressure variations.

- No backing-up with condensate.

- Excellent air discharge through its integrated air vent.

- Flow direction can be easily changed by repositioning the body in relation to the mechanism and cover.

- Equalizing (vent) and drain connections.

- SLR – Steam lock release.

- HVV – Hand vent valve.

- BDV – Blowdown valve.

- AFZ – Anti-freeze device.

- FLL – Float lifting lever.

- VB21M – Vacuum breaker

Saturated and superheated steam.

FLT37-4,5 , 10 , 21 and 32 – carbon steel.

11/2” to 2”; DN 40 to DN 50.

Female threaded ISO 7 Rp or NPT.

Flanged EN 1092-1 PN 40.

Flanged ASME B16.5 Class 150 or 300.

Socket weld ASME B16.11

Horizontal or vertical installation.

MAX. ΔP

FLT37-4,5 – 4,5 bar

FLT37-10 – 10 bar

FLT37-21 – 21 bar

FLT37-32 – 32 bar

Float and thermostatic steam traps FLT47 (Stainless steel 11/2” – 2”; DN 40 – 50)

The FLT47 is a range of float and thermostatic steam traps with integral air vent designed for modulating discharge of condensate, ensuring maximum system heat transfer.

Typical applications include unit heaters, heat exchangers, dryers, jacketed vessels and other applications where continuous discharge is essential and high flow capacities are involved.

- Modulating discharge of condensate at steam temperature.

- Unaffected by sudden or wide load and pressure variations.

- No backing-up with condensate.

- Excellent air discharge through its integrated air vent.

- Flow direction can be easily changed by repositioning the body in relation to the mechanism and cover.

- Equalizing (vent) and drain connections.

- SLR – Steam lock release.

- HVV – Hand vent valve.

- BDV – Blowdown valve.

- AFZ – Anti-freeze device.

- FLL – Float lifting lever.

- VB21M– Vacuum breaker.

Saturated and superheated steam.

FLT47-4,5 , 10 , 21 and 32 – stainless steel.

11/2” to 2”; DN 40 to DN 50

Female threaded ISO 7 Rp or NPT.

Flanged EN 1092-1 PN 40.

Flanged ASME B16.5 Class 150 or 300.

Socket weld ASME B16.11.

Horizontal or vertical installation

MAX. ΔP

FLT47-4,5 – 4,5 bar

FLT47-10 – 10 bar

FLT47-21 – 21 bar

FLT47-32 – 32 bar

Float and thermostatic steam traps FLT29 (SG iron ; 2" – DN 50)

The FLT29 is a range of float and thermostatic steam traps with integral air vent designed for modulating discharge of condensate, ensuring maximum system heat transfer.

Typical applications include unit heaters, heat exchangers, dryers, jacketed vessels and other applications where continuous discharge is essential and high flow capacities are involved.

- Modulating discharge of condensate at steam temperature.

- Unaffected by sudden or wide load and pressure variations.

- No backing-up with condensate.

- Excellent air discharge through its integrated air vent.

- Flow direction can be easily changed by repositioning the body in relation to the mechanism and cover.

- Equalizing (vent) and drain connections.

- SLR – Steam lock release.

- HVV – Hand vent valve.

- BDV – Blowdown valve.

- AFZ – Anti-freeze device.

- FLL – Float lifting lever. VB21M– Vacuum breaker.

Saturated and superheated steam.

FLT29-4,5 , 10 and 14 – SG iron.

2"; DN 50.

Female threaded ISO 7 Rp or NPT.

Flanged EN 1092-2 PN 16.

Flanged ASME B16.42 Class 150.

Horizontal or vertical installation.

MAX. ΔP

FLT29-4,5 – 4,5 bar

FLT29-10 – 10 bar

FLT29-14 – 14 bar

Float and thermostatic steam traps FLT39 (Carbon steel 2”; DN 50)

The FLT39 is a range of float and thermostatic steam traps with integral air vent designed for modulating discharge of condensate, ensuring maximum system heat transfer.

Typical applications include unit heaters, heat exchangers, dryers, jacketed vessels and other applications where continuous discharge is essential and high flow capacities are involved.

- Modulating discharge of condensate at steam temperature.

- Unaffected by sudden or wide load and pressure variations.

- No backing-up with condensate.

- Excellent air discharge through its integrated air vent.

- Flow direction can be easily changed by repositioning the body in relation to the mechanism and cover.

- Equalizing (vent) and drain connections.

- SLR – Steam lock release.

- HVV – Hand vent valve.

- BDV – Blowdown valve.

- AFZ – Anti-freeze device.

- FLL – Float lifting lever.

- VB21M– Vacuum breaker.

Saturated and superheated steam.

FLT39-4,5 , 10 , 21 and 32 – carbon steel.

2”; DN 50.

Female threaded ISO 7 Rp or NPT.

Flanged EN 1092-1 PN 40.

Flanged ASME B16.5 Class 150 or 300.

Socket weld ASME B16.11

Horizontal or vertical installation.

MAX. ΔP

FLT39-4,5 – 4,5 bar

FLT39-10 – 10 bar

FLT39-21 – 21 bar

FLT39-32 – 32 bar

Float and thermostatic steam traps FLT49 (Stainless steel 2”; DN 50)

The FLT49 is a range of float and thermostatic steam traps with integral air vent designed for modulating discharge of condensate, ensuring maximum system heat transfer.

Typical applications include unit heaters, heat exchangers, dryers, jacketed vessels and other applications where continuous discharge is essential and high flow capacities are involved.

- Modulating discharge of condensate at steam temperature.

- Unaffected by sudden or wide load and pressure variations.

- No backing-up with condensate.

- Excellent air discharge through its integrated air vent.

- Flow direction can be easily changed by repositioning the body in relation to the mechanism and cover.

- Equalizing (vent) and drain connections.

- SLR – Steam lock release.

- HVV – Hand vent valve.

- BDV – Blowdown valve.

- AFZ – Anti-freeze device.

- FLL – Float lifting lever.

- VB21M – Vacuum

Saturated and superheated steam.

FLT49-4,5 , 10 , 21 and 32 – stainless steel.

2”; DN 50.

Flanged EN 1092-1 PN 40.

Flanged ASME B16.5 Class 150 or 300.

Horizontal or vertical installation.

MAX. ΔP

FLT49-4,5 – 4,5 bar

FLT49-10 – 10 bar

FLT49-21 – 21 bar

FLT49-32 – 32 bar

Float and thermostatic steam traps FLT29TW (SG iron ; 3" and 4" – DN 80 and 100)

The FLT29TW is a range of high capacity float and thermostatic steam traps with integral air vent designed for modulating discharge of condensate, ensuring maximum system heat transfer.

Typical applications include unit heaters, heat exchangers, dryers, jacketed vessels and other applications where continuous discharge is essential and high flow capacities are involved.

- Modulating discharge of condensate at steam temperature.

- Unaffected by sudden or wide load and pressure variations.

- No backing-up with condensate. Excellent air discharge through its integrated air vent.

- Flow direction can be easily changed by repositioning the body in relation to the mechanism and cover.

- Equalizing (vent) and drain connections.

- HVV – Hand vent valve.

- BDV – Blowdown valve.

- AFZ – Anti-freeze device.

- VB21M – Vacuum breaker.

Saturated and superheated steam.

FLT29TW-4,5 , 10 and 14 – SG iron.

3" to 4"; DN 80 to DN 100.

Flanged EN 1092-1 PN 16.

Flanged ASME B16.5 Class 150.

Horizontal or vertical installation.

MAX. ΔP

FLT29TW-4,5 – 4,5 bar

FLT29TW-10 – 10 bar

FLT29TW-14 – 14 bar

Float and thermostatic steam traps FLT39TW (Carbon steel 3” – 4”; DN 80 – 100)

The FLT39TW is a range of high capacity float and thermostatic steam traps with integral air vent designed for modulating discharge of condensate, ensuring maximum system heat transfer.

Typical applications include unit heaters, heat exchangers, dryers, jacketed vessels and other applications where continuous discharge is essential and high flow capacities are involved.

- Modulating discharge of condensate at steam temperature.

- Unaffected by sudden or wide load and pressure variations.

- No backing-up with condensate.

- Excellent air discharge through its integrated air vent.

- Flow direction can be easily changed by repositioning the body in relation to the mechanism and cover.

- Equalizing (vent) and drain connections.

- HVV – Hand vent valve.

- BDV – Blowdown valve.

- AFZ – Anti-freeze device.

- VB21M – Vacuum breaker.

Saturated and superheated steam.

FLT39TW-4,5 , 10 , 21 and 32 – carbon steel.

3” to 4”; DN 80 to DN 100.

Flanged EN 1092-1 PN 16 or PN 40.

Flanged ASME B16.5 Class 150 or 300.

Horizontal or vertical installation.

MAX. ΔP

FLT39TW-4,5 – 4,5 bar

FLT39TW-10 – 10 bar

FLT39TW-21 – 21 bar

FLT39TW-32 – 32 bar

Float and thermostatic steam traps FLT49TW (Stainless steel 3” – 4”; DN 80 – 100)

The FLT49TW is a range of high capacity float and thermostatic steam traps with integral air vent designed for modulating discharge of condensate, ensuring maximum system heat transfer.

Typical applications include unit heaters, heat exchangers, dryers, jacketed vessels and other applications where continuous discharge is essential and high flow capacities are involved.

- Modulating discharge of condensate at steam temperature.

- Unaffected by sudden or wide load and pressure variations.

- No backing-up with condensate.

- Excellent air discharge through its integrated air vent.

- Flow direction can be easily changed by repositioning the body in relation to the mechanism and cover.

- Equalizing (vent) and drain connections.

- HVV – Hand vent valve.

- BDV – Blowdown valve.

- AFZ – Anti-freeze device.

- VB21M – Vacuum breaker.

Saturated and superheated steam

FLT49TW-4,5 , 10 , 21 and 32 – stainless steel.

3” to 4”; DN 80 to DN 100.

Flanged EN 1092-1 PN 16 or PN 40.

Flanged ASME B16.5 Class 150 or 300.

Horizontal or vertical installation.

MAX. ΔP

FLT49TW-4,5 – 4,5 bar

FLT49TW-10 – 10 bar

FLT49TW-21 – 21 bar

FLT49TW-32 – 32 bar

Float and thermostatic steam traps FLT151

The FLT151 is a series of high capacity float and thermostatic steam traps with integral air vent, designed for modulating discharge of condensate to ensure maximum system heat transfer.

Specially designed for applications where continuous drainage is essential and extremely high loads are involved, such as those found in sugar and alcohol refineries.

- High capacity.

- Modulating discharge of condensate at steam temperature.

- Unaffected by sudden or wide load and pressure variations.

- No backing-up with condensate.

- Excellent air discharge through its integrated thermostatic air vent.

- Level gauge.

- HVV – Hand vent valve.

- VB21M – Vacuum breaker.

Saturated steam.

FLT151S-O – carbon steel.

4” and 6”; DN 100 and DN 150.

Flanged EN 1092-1 PN 16.

Flanged ASME B16.5 Class 150.

Horizontal installation.

See IMI – Installation and maintenance instructions.

Bimetallic Steam Traps

Bimetallic steam traps and air vents BM20R

The BM20R series bimetallic steam traps and air vents are simple and robust traps, recommended for steam process applications where condensate sensible heat can be recovered, steam tracing lines, drip points, storage tank coils, steam air venting, etc. The use of condensate sensible heat reduces steam consumption.

- Modulating discharge.

- Discharges condensate below steam temperature. Easy condensate temperature adjustment without disconnecting the trap from the piping.

- Independent valve and seat placed in the low velocity flow area reduces erosion and extends product life.

- Low maintenance costs consequence of the split regulator design.

- Excellent air discharge.

- Freeze protection of condensate lines.

- Operates on superheated steam.

- Unaffected by water hammer and vibrations.

- Built-in strainer.

- Discharge valve.

- Seat with check valve.

Saturated and superheated steam.

BM20R - carbon steel, with external adjustable temperature control.

1/2" to 1"; DN 15 to DN 25.

Female thread ISO 7 Rp or NPT.

EN 1092-1 PN 40 flanges.

ASME B16.5 Class 150 or 300 flanges.

Socket weld (SW) ASME 16.11.

Butt weld (BW) ASME B16.25 on request.

Horizontal installation recommended, can be installed in any position.

See IMI - Installation and Maintenance Instructions.

Bimetallic steam traps and air vents DN40-125 BM HC

The BM–HC series of bimetallic steam traps and air vents are simple and robust traps, recommended for process applications where high loads are involved.

Tailor made to meet application requirements and supplied with several bimetallic regulators in order to achieve the required discharge capacity for the application in hands.

- Modulating discharge.

- Condensate discharge below steam saturation temperature.

- Excellent air removal.

- Works with superheated steam.

- Unaffected by vibration or water hammer.

- Built-in filter.

- Complete stainless steel construction.

- Different capacities and designs.

Saturated and superheated steam.

BM...HC04; BM...HC05; BM...HC06;

BM...HC08; BM...HC10.

11/2" to 5"; DN 40 to DN 125.

Flanges EN 1092-1 PN 63.

ASME B16.5 Class 900 flanges.

Vertical installation.

See IMI - Installation and maintenance instructions.

Bimetallic steam traps and air vents BM20

The BM20 series bimetallic steam traps and air vents are simple and robust traps, recommended for steam process applications where condensate sensible heat can be recovered, steam tracing lines, drip points, storage tank coils, steam air venting, etc. The use of condensate sensible heat reduces steam consumption.

- Modulating discharge.

- Condensate discharge below saturation temperature.

- Excellent air removal.

- Operates with superheated steam.

- Unaffected by water hammer and vibration.

- Built-in filter.

- Discharge valve.

Saturated and superheated steam.

BM20 - carbon steel.

1/2" to 1"; DN 15 to DN 25.

Female thread ISO 7 Rp or NPT.

Flanges EN 1092-1 PN 40.

Flanges ASME B16.5 Class 150 or 300.

Socket weld (SW) ASME 16.11.

Butt weld (BW) ASME B16.25 on request.

Horizontal installation recommended, can be installed in any position.

See IMI - Installation and maintenance instructions.

Bimetallic steam traps and air vents BM20i

The BM20i is a series of robust and efficient bimetallic steam traps and air vents. These steam traps are recommended for steam process applications where sensible heat can be recovered, such as steam tracing lines, drip points, storage tank coils and steam air venting.

- Modulating discharge.

- Discharges condensate below steam temperature.

- Excellent air discharge.

- Operates with superheated steam.

- Unaffected by water hammer and vibration.

- Built-in filter.

- Purge valve.

Saturated and superheated steam.

BM20i - stainless steel.

1/2" to 1"; DN 15 to DN 25.

Female thread ISO 7 Rp or NPT.

Flanged EN 1092-1 PN 40.

Flanged ASME B16.5 Class 150 or 300.

Socket weld (SW) ASME 16.11.

Butt weld (BW) ASME B16.25 on request.

Horizontal in-line installation is recommended.

See IMI - Installation and Maintenance Instructions.

Bimetallic steam traps and air vents BM24 (1/2" to 1" – DN 15 to DN 25)

The BM24 series bimetallic steam traps and air vents are simple and robust traps, recommended for steam process applications where condensate sensible heat can be recovered, steam tracing lines, drip points, storage tank coils, steam air venting, etc. The use of condensate sensible heat reduces steam consumption.

- Modulating discharge.

- Condensate discharge below steam saturation temperature.

- Excellent air removal.

- Works with superheated steam.

- Unaffected by vibration or water hammer.

- Built-in filter

- Discharge valve.

- BM24 - carbon steel

Saturated and superheated steam.

1/2" to 1" ; DN 15 to DN 25

Female thread ISO 7 Rp or NPT.

Flanges EN 1092-1 PN 40.

Flanges ASME B16.5 Class 150 or 300.

Socket weld (SW) ASME 16.11.

Butt weld (BW) ASME B16.25 on request.

Horizontal installation recommended, can be installed in any position.

See IMI - Installation and maintenance instructions.

Bimetallic steam traps and air vents BM32 (1/2" to 1" – DN 15 to DN 25)

The BM32 series of steam traps and air eliminators are simple and robust traps, recommended for steam process applications where sensible heat can be recovered from condensate, steam tracer lines, drip pits, storage tank coils, air venting, etc. The use of sensible heat from condensate reduces steam consumption. Connections are female threaded or flanged PN40. Manufactured in carbon steel.

- Modulating discharge.

- Condensate discharge below steam saturation temperature.

- Excellent air elimination.

- Works with superheated steam.

- Unaffected by vibration or water hammer.

- Built-in filter.

- Discharge valve.

Saturated and superheated steam.

BM32 - carbon steel.

1/2" to 1"; DN 15 to DN 25.

Female thread ISO 7 Rp or NPT.

Flanges EN 1092-1 PN 40.

Flanges ASME B16.5 Class 150 or 300.

Socket weld (SW) ASME B16.11.

Butt weld (BW) ASME B16.25 on request.

Horizontal installation recommended, can be installed in any position.

See IMI - Installation and maintenance instructions.

Bimetallic steam traps and air vents BM87

The BM87 is a series of robust and efficient bimetallic steam traps and air vents. These steam traps are recommended for steam process applications where sensible heat can be recovered, such as steam tracing lines, drip points, storage tank coils and steam air venting.

- Modulating discharge.

- Discharges condensate below steam saturation temperature.

- Excellent air discharge.

- Works with superheated steam.

- Unaffected by water hammer and vibration.

- Built-in filter.

Saturated and superheated steam.

BM87 - carbon steel.

1/2" to 1"; DN 15 to DN 25.

Female thread ISO 7 Rp or NPT.

Flanged EN 1092-1 PN 40 or PN 63.

Flanged ASME B16.5 Class 300 or 600.

Socket weld (SW) ASME B16.11.

Butt weld (BW) ASME B16.25.

Horizontal in-line installation is recommended.

See IMI - Installation and Maintenance Instructions

Bimetallic steam traps and air vents BM88

The BM88 is a series of robust and efficient bimetallic steam traps and air vents. These steam traps are recommended for steam process applications where sensible heat can be recovered, such as steam tracing lines, drip points, storage tank coils and steam air venting. Specially designed for draining high pressure superheated steam lines and processes.

- Modulating discharge.

- Discharges condensate below steam saturation temperature.

- Excellent air discharge.

- Works with superheated steam.

- Unaffected by water hammer and vibration.

- Built-in filter.

Saturated and superheated steam.

BM88 - carbon steel.

1/2" to 1"; DN 15 to DN 25.

Female thread ISO 7 Rp or NPT.

Flanged EN 1092-1 PN 100.

Flanged ASME B16.5 Class 600.

Socket weld (SW) ASME B16.11.

Butt weld (BW) ASME B16.25.

Horizontal in-line installation is recommended.

See IMI - Installation and Maintenance Instructions

Bimetallic steam traps and air vents BM89

The BM89 is a series of robust and efficient bimetallic steam traps and air vents. These steam traps are recommended for steam process applications where sensible heat can be recovered, such as steam tracing lines, drip points, storage tank coils and steam air venting. Specially designed for draining high pressure superheated steam lines and processes.

- Modulating discharge.

- Discharges condensate below steam saturation temperature.

- Excellent air discharge.

- Works with superheated steam.

- Unaffected by water hammer and vibration.

- Built-in filter.

Saturated and superheated steam.

BM89 - carbon steel.

1/2" to 1"; DN 15 to DN 25.

Female thread ISO 7 Rp or NPT.

Flanged EN 1092-1 PN 160.

Flanged ASME B16.5 Class 900.

Socket weld (SW) ASME B16.11.

Butt weld (BW) ASME B16.25.

Horizontal in-line installation is recommended.

See IMI - Installation and Maintenance Instructions.

Bimetallic steam traps and air vents BM90

The BM90 is a series of robust and efficient bimetallic steam traps and air vents. These steam traps are recommended for steam process applications where sensible heat can be recovered, such as steam tracing lines, drip points, storage tank coils and steam air venting. Specially designed for draining high pressure superheated steam lines and processes..

- Modulating discharge.

- Discharges condensate below steam temperature.

- Excellent air removal.

- Works with superheated steam.

- Unaffected by vibration or water hammer.

- Built-in filter.

Saturated and superheated steam.

BM90 - carbon steel.

1/2" to 1"; DN 15 to DN 25.

Female thread ISO 7 Rp or NPT.

Flanged EN 1092-1 PN 250.

Flanged ASME B16.5 Class 1500.

Socket weld (SW) ASME B16.11.

Butt weld (BW) ASME B16.25.

Horizontal in-line installation is recommended.

See IMI - Installation and Maintenance Instructions.

Bimetallic steam traps and air vents BSS20

The BSS20 all stainless steel bimetallic steam traps and air vents are simple and robust traps, specially suited for instrument tracing, line tracing applications and where condensate sensible heat can be recovered. The use of condensate sensible heat reduces steam consumption.

The BSS20 is especially suitably for air venting applications.

- Modulating discharge.

- Condensate discharge below steam saturation temperature.

- Excellent air removal.

- Works with superheated steam.

- Unaffected by vibration or water hammer.

- Built-in filter.

Saturated and superheated steam.

BSS20 - stainless steel.

1/2".

Female thread ISO 7 Rp or NPT.

Horizontal or vertical installation.

See IMI - Installation and maintenance instructions

Bimetallic steam traps and air vents BM24 (11/2" and 2" – DN 40 and DN 50)

The BM24 series bimetallic steam traps and air vents are simple and robust traps, recommended for steam process applications where condensate sensible heat can be recovered, steam tracing lines, drip points, storage tank coils, steam air venting, etc. The use of condensate sensible heat reduces steam consumption.

- Modulating discharge.

- Condensate discharge below steam saturation temperature.

- Excellent air removal.

- Works with superheated steam.

- Unaffected by vibration or water hammer.

- Built-in filter.

Saturated and superheated steam.

BM24 - carbon steel.

11/2" and 2"; DN 40 and DN 50.

Female thread ISO 7 Rp or NPT.

Flange EN 1092-1 PN 40.

Flanged ASME B16.5 Class 150 or 300.

Socket weld (SW) ASME B16.11.

Butt weld (BW) ASME B16.25.

Horizontal installation recommended, can be installed in any position.

can be installed in any position.

See IMI - Installation and Maintenance Instructions

Bimetallic steam traps and air vents BM32 (11/2" and 2" – DN 40 and DN 50)

The BM32 series bimetallic steam traps and air vents are simple and robust traps, recommended for steam process applications where condensate sensible heat can be recovered, steam tracing lines, drip points, storage tank coils, steam air venting, etc. The use of condensate sensible heat reduces steam consumption.

- Modulating discharge.

- Condensate discharge below steam saturation temperature.

- Excellent air removal.

- Works with superheated steam.

- Unaffected by vibration or water hammer.

- Built-in filter.

Saturated and superheated steam.

BM32 - carbon steel.

11/2" and 2"; DN 40 and DN 50.

Female thread ISO 7 Rp or NPT.

Flanged EN 1092-1 PN 40.

Flanged ASME B16.5 Class 150 or 300.

Socket weld (SW) ASME B16.11.

Butt weld (BW) ASME B16.25.

Horizontal installation recommended, can be installed in any position.

can be installed in any position.

See IMI - Installation and Maintenance Instructions

Thermostatic Steam Trap

Thermostatic steam traps and air vents TSS22

The TSS22 series deaerator and air eliminator is specifically designed for use on process equipment such as boiling kettles, sterilizers, food, chemical and laundry machinery. Its small size makes it ideal for use in a wide variety of equipment and applications as a steam deaerator.

- Modulating discharge

- Condensate discharge near saturation temperature

- Various thermostats for different cooling temperatures (5º or 30ºC).

- Excellent air elimination.

- Works with moderately superheated steam.

- Built-in filter.

Saturated steam

TSS22, TSS22H - stainless steel.

1/4" a 1".

ISO 7 Rp or NPT female threads.

Horizontal or vertical installation.

See IMI - Installation and maintenance instructions.

Thermostatic steam traps and air vents TH32i

The TH32i series thermostatic steam traps and air vents are specifically designed for use on process equipment such as kettle cookers, sterilizers, food, chemical and laundry equipment.

- Modulating discharge.

- Discharges condensate close to steam temperature.

- Thermostats for different sub cooling (5 ºC to 30 ºC).

- Excellent air discharge.

- Operates on moderate superheated steam.

- Built-in strainer.

- LC - low capacity.

- Integrated check valve.

- Purge valve

Saturated steam.

TH32i - stainless steel.

TH32i-CK - stainless steel, with check valve.

1/2" to 1"; DN 15 to DN 25.

Female thread ISO 7 Rp or NPT.

Flanged EN 1092-1 PN 40.

Flanged ASME B16.5 Class 150 or 300.

Socket weld (SW) ASME 16.11.

Butt weld (BW) ASME B16.25 on request.

Horizontal installation recommended, can be installed in any position.

See IMI - Installation and Maintenance Instructions.

Thermostatic steam traps and air vents TH32Y

The TH32Y series thermostatic steam traps and air vents are specifically designed for use on process equipment such as kettle cookers, sterilizers, food, chemical and laundry equipment.

- Modulating discharge

- Condensate discharge close to saturation temperature

- Various thermostats for different cooling temperatures (5º or 30ºC)

- Excellent air elimination.

- Works with moderately superheated steam.

- Built-in filter

- Discharge valve.

- Built-in check valve.

Saturated steam

TH32Y - carbon steel.

TH32YLC - low capacity, carbon steel.

Suffix "CK": Version with built-in check valve.

1/2" to 1"; DN 15 to DN 25.

Female thread ISO 7 Rp or NPT.

Flanges EN 1092-1 PN 40.

Flanges ASME B16.5 Class 150 or 300.

Socket weld (SW) ASME 16.11.

Butt weld (BW) ASME B16.25 on request.

Horizontal installation recommended, can be installed in any position.

See IMI - Installation and Maintenance Instructions.

Thermostatic steam traps and air vents TH13A

The TH13A series thermostatic steam traps and air vents are specifically designed for use on process equipment such as kettle cookers, sterilizers, food, chemical and laundry equipment.

Their small size makes them ideal for use with a wide variety of this equipment and, specially, as air vents.

- Modulating discharge

- Condensate discharge close to saturation temperature

- Various thermostats for different cooling temperatures (5º or 30ºC)

- Excellent air elimination.

- Works with moderately superheated steam.

- Built-in filter.

Saturated steam.

TH13A - brass

1/2".

Female thread ISO 7 Rp

Vertical installation, angled connections.

See IMI – Installation and maintenance instructions.

Thermostatic steam traps and air vents TH21

The TH21 series thermostatic steam traps and air vents are specifically designed for use on process equipment such as kettle cookers, sterilizers, food, chemical and laundry equipment.

- Modulating discharge

- Condensate discharge close to saturation temperature

- Various thermostats for different cooling temperatures (5º or 30ºC)

- Excellent air elimination.

- Works with moderately superheated steam.

- Built-in filter

Saturated steam.

TH21 - carbon steel.

TH21LC - carbon steel, low capacity.

1/2"; DN 15.

Female thread ISO 7 Rp or NPT.

Flanges EN 1092-1 PN 25.

Flanges ASME B16.5 Class 150.

Socket weld (SW) ASME 16.11.

Butt weld (BW) ASME B16.25 on request.

Thermostatic steam traps and air vents TH35/2 and TH35/3

The TH35 series thermostatic steam traps and air vents are specifically designed for use on process equipment such as kettle cookers, sterilizers, food, chemical and laundry equipment

- Modulating discharge

- Condensate discharge close to saturation temperature

- Various thermostats for different cooling temperatures (5º or 30ºC)

- Excellent air elimination.

- Works with moderately superheated steam.

- Built-in filter.

Saturated steam

TH35/2 - carbon steel, 2 capsules.

TH35/3 - carbon steel, 3 capsules.

1" - DN 25.

Female thread ISO 7 Rp or NPT.

Flanges EN 1092-1 PN 40.

Flanges ASME B16.5 Class 150 or 300.

Socket weld (SW) ASME 16.11.

Butt weld (BW) ASME B16.25 on request.

Horizontal installation recommended, can be installed in any position. See IMI - Installation and maintenance instructions.

Thermostatic steam traps and air vents TH36/4 – TH36/6 TH36

The TH36 series thermostatic steam traps and air vents are specifically designed for use on process equipment such as kettle cookers, sterilizers, food, chemical and laundry equipment where high discharge capacities are required.

- Modulating discharge

- Condensate discharge close to saturation temperature

- Various thermostats for different cooling temperatures (5º or 30ºC)

- Excellent air elimination.

- Works with moderately superheated steam.

- Built-in filter.

Saturated steam

TH36/4 - carbon steel, 4 capsules.

TH36/6 - carbon steel, 6 capsules.

11/2" to 2"; DN 40 to DN 50.

Female thread ISO 7 Rp or NPT.

Flanges EN 1092-1 PN 40.

ASME B16.5 Class 150 or 300 flanges.

Socket weld (SW) ASME 16.11.

Butt weld (BW) ASME B16.25.

Horizontal installation recommended, can be installed in any position.

See IMI - Installation and Maintenance Instructions.

Thermostatic steam traps and air vents TSW22

The TSW22 all stainless steel thermostatic steam traps and air vents are specifically designed for use on process equipment such as kettle cookers, sterilizers, food, chemical and laundry equipment. Their small size makes them ideal for use with a wide variety of this equipment.

- Modulating discharge.

- Condensate discharge close to saturation temperature.

- Thermostats for different subcooling (5 ºC to 30 ºC).

- Excellent air elimination.

- Operates with moderately superheated steam.

- Simple and compact design.

- Can operate in any position.

Saturated steam

TSW22 - stainless steel, wafer design.

DN 15 to DN 25.

Wafer type between flanges according to EN 1092-1 PN 40.

Any position.

See IMI - Installation and maintenance instructions.

Inverted Bucket Steam Trap

Inverted bucket steam traps IB12

The IB12 is a series of general purpose robust and versatile inverted bucket steam traps manufactured in SG iron.

These steam traps operate intermittently and are suitable for use with saturated or superheated steam.

Typical applications include drip points, steam tracing lines, dryers, chemical and laundry equipment.

- Intermittent discharge.

- Discharges condensate at steam temperature.

- Unaffected by water hammer and vibrations.

- Easy to maintain.

Saturated and superheated steam.

IB12-4, 8 and 12 – SG iron

Female threaded ISO 7 Rp or NPT.

Screw-on flanges EN 1092-2 PN 16/40.

Screw-on flanges ASME B16.42 Class 150

Horizontal installation.

See IMI – Installation and maintenance instructions.

MAX. ΔP

IB12-4 – 4 bar

IB12-8 – 8 bar

IB12-12 – 12 bar

Inverted bucket steam traps IB30 (11/2” – 2”; DN 40 – DN 50)

The IB30 series inverted bucket steam traps are recommended for applications where the most important requirements are overall operating efficiency and long, trouble-free service life.

They operate intermittently, either wide open or tightly closed and are, therefore, best suited for medium and high steam pressure applications.

- Intermittent discharge.

- Discharges condensate at steam temperature.

- Unaffected by water hammer and vibrations.

- Easy to maintain.

- Cover connection with plug (mandatory if any of the below options are considered).

- BDV – Blowdown valve.

- AFZ – Anti-freeze device.

Saturated and superheated steam.

IB30S-4, 8 and 12 – carbon steel.

11/2” to 2”; DN 40 to DN 50.

Female threaded ISO 7 Rp or NPT.

Flanged EN 1092-1 PN 25

Flanged ASME B16.5 Class 150 or 300.

Socket weld (SW) ASME 16.11.

Butt weld (BW) ASME B16.25 on request.

Vertical installation.

See IMI – Installation and maintenance instructions.

MAX. ΔP

IB30S-4 – 4 bar

IB30S-8 – 8 bar

IB30S-12 – 12 bar

Inverted bucket steam traps IB30S

The IB30S is a series of rugged and versatile general purpose inverted bucket steam traps made of carbon steel.

These traps operate intermittently and are suitable for use with saturated or superheated steam.

Typical applications include drip points, steam tracer lines, dryers, chemical and laundry equipment.

- Intermittent discharge.

- Condensate flow at saturation temperature.

- Insensitive to sudden variations in pressure and flow rate.

- Easy maintenance.

OPTIONAL

- BDV - Blowdown valve.

- AFZ - Antifreeze device.

- Cover connection with plug (mandatory if any of the below options are considered).

- BDV – Blowdown valve.

- AFZ – Anti-freeze device.

Saturated and superheated steam

IB30S-4, 8, 12 and 17 – carbon steel.

1/2" to 1".

Female threaded ISO 7 Rp or NPT.

Socket weld (SW) ASME 16.11.

Butt weld (BW) ASME B16.25 on request.

Horizontal installation.

See IMI – Installation and maintenance instructions.

MAX. ΔP

IB30S-4 – 4 bar

IB30S-8 – 8 bar

IB30S-12 – 12 bar

IB30S-17 – 17 bar

Inverted bucket steam traps IB30SS

Series IB30SS inverted bucket steam traps are recommended for all services where the most important requirements are overall operating efficiency and a long, trouble-free service life.

They operate intermittently, either open or hermetically closed and are therefore best suited for medium and high steam pressure applications. Manufactured in stainless steel.

Connections are threaded or female flanged.

- Intermittent discharge.

- Discharges condensate at steam temperature.

- Unaffected by water hammer and vibrations.

- Easy maintenance.

- BDV - Blowdown valve.

- AFZ - Antifreeze device.

Saturated and superheated steam.

B30SS-4, 8, 12 and 17 – stainless steel.

1/2" to 1".

Female threaded ISO 7 Rp or NPT.

Socket weld (SW) ASME 16.11.

Butt weld (BW) ASME B16.25 on request.

Horizontal installation.

See IMI – Installation and maintenance instructions.

MAX. ΔP

IB30SS-4 – 4 bar

IB30SS-8 – 8 bar

IB30SS-12 – 12 bar

IB30SS-17 – 17 bar

Inverted bucket steam traps IB36i

IB36i inverted bucket traps are rugged and versatile stainless steel traps. They operate intermittently and are suitable for use with low to high pressure saturated or superheated steam.

Typical applications include drip points, steam tracer lines, dryers, chemical and laundry equipment.

- Intermittent discharge.

- Discharges condensate at steam temperature.

- Unaffected by water hammer and vibration.

- Robust and versatile.

- Easy to maintain.

- BDV - Blowdown valve.

- AFZ - Antifreeze device.

Saturated and superheated steam.

IB36i-5, 10, 15 and 27 – stainless steel.

1/2" to 1"; DN 15 to DN 25

Female threaded ISO 7 Rp or NPT.

Flanged EN 1092-1 PN 40.

Flanged ASME B16.5 Class 150 or 300.

Socket weld (SW) ASME B16.11.

Butt weld (BW) ASME B16.25 on request.

Horizontal installation.

See IMI – Installation and maintenance instructions.

MAX. ΔP

IB36i-5 – 5 bar

IB36i-10 – 10 bar

IB36i-15 – 15 bar

IB36i-27 – 27 bar

Inverted bucket steam traps IB36S

IB36S inverted bucket traps are rugged and versatile carbon steel traps. They operate intermittently and are suitable for use with low to high pressure saturated or superheated steam. Typical applications include drip points, steam tracer lines, dryers, chemical and laundry equipment.

- Intermittent discharge.

- Discharges condensate at steam temperature.

- Unaffected by water hammer and vibration.

- Robust and versatile.

- Easy to maintain.

- BDV - Blowdown valve.

- AFZ - Antifreeze device

Saturated and superheated steam.

IB36S-5, 10, 15, 30 and 40 – carbon steel.

1/2" to 1"; DN 15 to DN 25.

Female threaded ISO 7 Rp or NPT.

Flanged EN 1092-1 PN 40.

Flanged ASME B16.5 Class 150 or 300.

Socket weld (SW) ASME B16.11.

Butt weld (BW) ASME B16.25 on request.

Horizontal installation.

See IMI – Installation and maintenance instructions.

MAX. ΔP

IB36S-5 – 5 bar

IB36S-10 – 10 bar

IB36S-15 – 15 bar

IB36S-30 – 30 bar

IB36S-40 – 40 bar

Inverted bucket steam traps IBB12

IBB12 inverted bucket traps are recommended for all types of services where the most important requirement is efficient maintenance-free operation. They operate intermittently, or completely open or closed, being very suitable for working with steam at medium and high pressures. Connections are threaded for horizontal application.

- Intermittent discharge.

- Condensate flow at saturation temperature.

- Insensitive to sudden variations in pressure and flow rate.

- Easy maintenance

Saturated and superheated steam.

IBB12-4, 8 and 12 – SG iron.

3/4” to 1” – DN 20 to DN 25.

Female threaded ISO 7 Rp or NPT.

Screw-on flanges EN 1092-2 PN 16/40.

Screw-on flanges ASME B16.42 Class 150.

Horizontal installation.

See IMI – Installation and maintenance instructions

MAX. ΔP

IBB12-4 – 4 bar

IBB12-8 – 8 bar

Compact Universal Steam Trap Station - UNIADCA

Universal pipeline connectors UCX90

The UCX series pipeline connectors are used in steam systems where a simple and economic maintenance program is desired.

Typical installations are drip service on steam lines, tracing applications and small process equipment.

The four-bolt flange connector allows for fast trap replacement without disturbing the pipelines.

The UCX connector fits the universal four-bolt swivel connection steam traps.

- Remains permanently in line, which facilitates and speeds up the replacement of new traps.

- Traps can rotate 360º, allowing any piping orientation during installation.

- Universal flange allows the trap to be placed in the correct position, regardless of piping configuration.

- Built-in filter.

- Compatible with UniAdca compact series of traps.

Purge valve.

Saturated and superheated steam.

UCX90 - stainless steel

1/2" to 1"; DN 15 to DN 25.

Female thread ISO 7 Rp or NPT.

Flanged EN 1092-1 PN 100.

Flanged ASME B16.5 Class 600.

Socket weld (SW) ASME B16.11. With surface for rotary connection in a vertical plane (steam traps). vertical plane (mechanical steam traps) or, alternatively, in a horizontal plane for thermostatic steam traps.

See IMI - Installation and Maintenance Instructions instructions.

Universal pipeline connectors UCX41

The UCX series pipeline connectors are used in steam systems where a simple and economic maintenance program is desired.

Typical installations are drip service on steam lines, tracing applications and small process equipment.

The two-bolt flange connector allows for fast trap replacement without disturbing the pipelines. The UCX connector fits the universal swivel connection steam traps.

- Remains permanently in-line making the replacement of new traps easier and quicker.

- Steam traps can swivel 360º, allowing any pipe orientation during installation.

- The universal flange allows the trap to be positioned in the correct position, regardless of pipeline configuration.

- Built-in strainer.

- Blowdown valve

Saturated and superheated steam.

UCX41 – stainless steel.

1/2” to 1”; DN 15 to DN 25.

Female threaded ISO 7 Rp or NPT.

Flanged EN 1092-1 PN 40.

Flanged ASME B16.5 Class 150 or 300.

Socket weld (SW) ASME B16.11.

Butt weld (BW) ASME B16.25 on request.

With the surface for swivel connection in a vertical plane (mechanical steam traps) or, alternatively, in an horizontal plane for thermostatic steam traps.

See IMI – Installation and maintenance instructions.

Compact trapping station CTS4U (For use with universal swivel connector steam traps)

The UniADCA CTS4U is a complete and compact steam trapping station designed to be used as an alternative to traditional multi-component trap stations, simplifying maintenance and reducing downtime and associated costs.

The swivel connector allows steam trap replacement in only a few minutes without disturbing the pipeline.

Compatible with “two-bolt” UniADCA universal steam traps and other universal steam traps with swivel connector.

Typical installations include drip service on steam lines, tracing, SKID’s and small process equipment.

- Built-in strainer and check valve.

- Reduced downtime and costs due to easy in-line maintenance.

- Safe depressurization through bleed valve or BDV.

- Available with double upstream shut-off valves.

- Universal steam traps can swivel 360°, allowing the steam trap to be fitted in the correct position, regardless of pipeline configuration.

- BDV – Blowdown valve.

Saturated and superheated steam.

CTS4U – stainless steel, with inlet and outlet shut-off valves.

CTS4UD – stainless steel, with double inlet shut- -off valves.

CTS4UDB – stainless steel, with double inlet shut-off valves and bleed valve.

1/2” to 1”; DN 15 to DN 25.

Female threaded ISO 7 Rp or NPT.

Flanged EN 1092-1 PN 40.

Flanged ASME B16.5 Class 150 or Class 300.

See IMI – Installation and maintenance instructions.

Universal bimetal steam trap UNIADCA UBS90

(For use with universal four-bolt pipe fittings)

The all stainless steel UBS90 Series bimetallic steam traps and air eliminators are maintenance-free, sealed traps.

Simple and rugged, they are recommended for drip service, steam tracing applications and where sensible heat can be recovered from condensate.

These traps fit UCX90 universal four-screw connectors.

- Sealed, non-maintainable.

- Modulating discharge.

- Discharges condensate below steam temperature.

- Excellent air discharge.

- Operates with superheated steam.

- Unaffected by water hammer and vibration.

- Different operating limits.

Saturated and superheated steam.

UBS90/4 and UBS90/6 - stainless steel.

Depending on pipe connector selected.

With the bimetallic column in a horizontal plane facing upwards.

See IMI - Installation and maintenance instructions

Compact bimetallic air bleeders UNIADCA UBS20

(For use with universal pipeline connectors)

The maintenance-free UnidAdca UBS20 series air trap and air eliminator are simple and robust traps, recommended for use in drip wells, tracing and all those applications where sensible heat from condensate can be recovered. This series of traps are installed with UCX universal connectors.

- Sealed body, maintenance free

- Modulating discharge.

- Condensate discharge below steam saturation temperature.

- Excellent air elimination.

- Works with superheated steam.

- Unaffected by vibration or water hammer.

- Different operating limits.

Saturated and superheated steam.

UBS20 - stainless steel.

According to the connector selected.

In any position.

See IMI - Installation and maintenance instructions.

Float and thermostatic steam traps UFS32

(For use with universal pipeline connectors)

The UFS32 series of all stainless steel, maintenance-free, sealed float traps with built-in air eliminator are designed specifically for use with low and medium pressure steam and all types of heating and process equipment.

They are specifically designed to work with low and medium pressure steam and all types of heating and process equipment.

Typical applications include fan heaters, heat exchangers, dryers, double-walled tanks and all applications where continuous condensate discharge is essential.

These traps fit UCX universal connectors and CTS4U compact stations.

- Maintenance-free sealed body

- Modulating discharge.

- Discharges condensate at steam temperature.

- Unaffected by sudden or large changes in load or pressure.

- Excellent air discharge (due to thermostatic venting).

Saturated and superheated steam.

UFS32-4,5 , 10, 14, 14, 21 and 32 - stainless steel.

According to the connector selected.

Always in a horizontal plane with the "O" of the TOP inscription perfectly aligned with the vertical axis.

See IMI - Installation and maintenance instructions.

MAX. ΔP

UFS32-4,5 – 4,5 bar

UFS32-10 – 10 bar

UFS32-14 – 14 bar

UFS32-21 – 21 bar

UFS32-32 – 32 bar

Inverted bucket steam traps UIB36 (For use with universal pipeline connectors)

(For use with universal pipeline connectors)

The UIB36 series inverted bucket steam traps, completely in stainless steel, are maintenance free and sealed. These steam traps operate intermittently, and are suitable for use with low to high pressure saturated or superheated steam.

Typical applications include drip points, steam tracing lines, dryers, chemical and laundry equipment.

These traps fit the UCX universal connectors and CTS4U compact stations.

- Maintenance-free sealed body

- Intermittent discharge.

- Discharges condensate at steam temperature

- Sealed, non-maintainable.

- Intermittent discharge.

- Discharges condensate at steam temperature.

Sealed, non-maintainable.

Intermittent discharge.

Condensate discharge at steam temperature.

UIB36-5 , 10, 15 and 27 - stainless steel.

Depending on pipe connector selected.

With the protruding body section pointing downward.

See IMI - Installation and Maintenance Instructions

Thermodynamic steam trap UDT46 (For use with universal pipeline connectors)

(For use with universal pipeline connectors)

The UDT46 series thermodynamic steam traps, completely in stainless steel, are excellent for high pressure systems, including steam tracing applications.

The insulation cover ensures a consistent operation and makes them particularly suitable for applications where the weather conditions, such as rain and wind, may affect the normal operation.

These traps have only one moving part and offer a wide operating range, without adjustment.

These traps fit the UCX universal connectors and CTS4U compact stations.

- Intermittent discharge.

- Standard insulation cover.

- Operates with superheated steam.

- Replaceable seat and disc.

- Unaffected by water hammer and vibration.

Saturated and superheated steam.

UDT46 - stainless steel.

According to the connector selected.

With the insulating cap pointing upwards.

See IMI - Installation and maintenance instructions.

Thermostatic steam trap UTS22 (For use with universal pipeline connectors)

(For use with universal pipeline connectors)

The UTS22 series thermostatic steam traps and air eliminators, completely in stainless steel, are maintenance free and sealed traps. They are specifically designed to be used on process equipment such as kettle cookers, sterilizers, food, chemical and laundry equipment.

These traps fit the UCX universal connectors and CTS4U compact stations.

- Sealed, non-maintainable.

- Modulating discharge.

- Discharges condensate close to steam temperature.

- Thermostats for different sub cooling temperatures (5 ºC to 30 ºC).

- Excellent air discharge.

- Operates on moderate superheated steam.

Saturated steam.

UTS22 – stainless steel.

UTS22LC – stainless steel, low capacity.

According to the selected pipeline connector.

In any position.

See IMI – Installation and maintenance instructions.

Miscellaneous

Ultrasonic detector UTT100

The UTT 100 ultrasonic trap tester is a battery-powered instrument that provides both an optical and an acoustic indication of ultrasonic frequencies. It provides easy and reliable mechanical inspection and leak detection using ultrasonic technology. Before performing the check it is advisable to familiarize yourself with the basic components of the kit.

The UTT-100 consists of 3 main components:

- Gun housing

- Contact module (stethoscope)

- Auricule

Noise diffusers DF15

The ADCA DF series are compact noise diffusers designed to disperse the high velocity discharge from steam or air traps, dampening noise and reducing erosion. These devices are typically installed downstream of intermittent steam traps, such as thermodynamic or inverted bucket traps, which are often associated with high velocity discharges. Noise reductions in excess of 80% can be expected when measured at a distance of 1 meter from the source.

- Simple and compact design

- 80% noise reduction, measured at 1 meter from the application.

- Corrosion resistant.

- No moving parts.

Steam or compressed air.

DF15 - outlet with threaded connection, suitable when discharging to condensate return lines.

DF16 - outlet without threaded connection, suitable for direct discharge to atmosphere.

1/2", 3/4" and 1".

ISO 7 Rp female thread.

Recommended installation position is vertical with outlet connection facing downward to the floor or other safe location. Clean before installing the diffuser.

On compressed air systems, make sure the system is oil free.

See IMI - Installation and Maintenance Instructions.

VB21 Vaccum breaker

VB21 vacuum breakers are simple and reliable devices that automatically relieve or "break" an unwanted vacuum condition by restoring atmospheric pressure.

This device is particularly suitable for small to medium volume steam heated units such as heat exchangers, heating coils, accumulators, jacketed boilers, steam boilers, etc.

Saturated and superheated steam.

VB21 - female thread.

VB21M - male thread.

1/2" x 1/8".

System: 1/2" vertical connection.

Air inlet: horizontal connection 1/8".

VB21 - female thread ISO 7 Rp or NPT.

VB21M - male thread ISO 228 G.

Vertical installation with angle connection.

See IMI - Installation and maintenance instructions

CDV32 condensate drain valve

CDV32 condensate discharge valves automatically discharge air and condensate from steam systems during start-up. A compression spring keeps the valve open when the system is not pressurized. As soon as

the operating pressure reaches the closing pressure to which the CDV is set, the valve closes. If the operating pressure drops below the set closing pressure, the spring force will cause the CDV32 to open once again.

- Manual relief lever to operate the valve under operating pressure under pressure for dirt removal.

- Prevents vacuum and ice formation.

- Built-in filter, easy to clean.

Saturated steam.

CDV32 - carbon steel.

1/2" to 3/4"; DN 15 to DN 20.

Female thread ISO 7 Rp or NPT.

Flanges EN 1092-1 PN 40.

Flanges ASME B16.5 Class 150 or 300.

Socket weld (SW) ASME B16.11.

Butt weld (BW) ASME B16.25 on request.

Vertical installation recommended.

When installed in horizontal lines, an outlet connection pipe should be installed.

When installed in horizontal lines, a downward pointing outlet connection pipe must be installed.

See IMI - Installation and Maintenance Instructions.

Blowdown / depressurization and vent valves BDV, BDVL, HVV and AFZ